|

HISTORIC WORLD 1ST FIRST

THE WORLD'S FIRST HYDROGEN CARTRIDGE FCEV CAR 2014

Please use our A-Z to navigate this site or return HOME

|

||||||||||

|

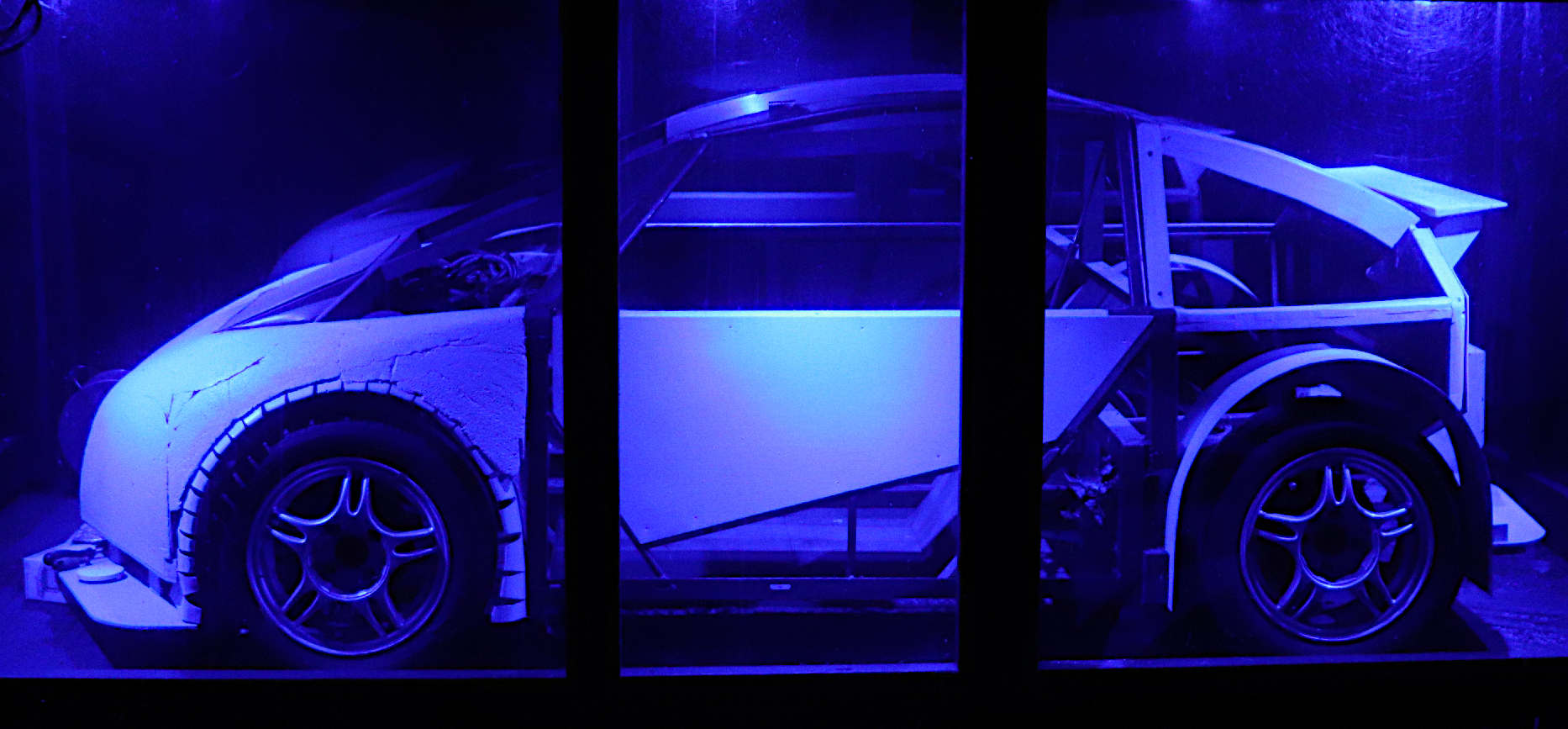

YOU LITTLE BEAUTY - It may look like a Bugatti, but this hand-built compact gull-wing sports car is not an Italian stallion, it is a British bulldog. Electric cars were more popular as a mode of transport, until the electric starter motor made it easy to operate petrol and diesel engines, powered by fossil fuels. Today the challenge is to make automotive transport clean, in a sustainable world, for a healthier future. The city sports car from 2014 is seen here in it's display case, in Sussex, England. Imagine cars like this on the road, powered by ammonia, methanol or compressed hydrogen. The inbuilt cartridge system means it can swap between fuel technology at the flick of a switch. In reality, around 90 - 120 seconds. Around $150,000 dollars would see this (or a very similar design) vehicle with a body, trimmed upholstery and a prototype 'universal' cartridge design. If designed and completed by students. Otherwise, add at least another two zeros. But even so, where would that funding come from? The JVH2 may help entrepreneurs raise interest, with live projects like this and philanthropic support.

|

||||||||||

|

The world's first EV, fitted with a hydrogen cartridge exchange system, was hand built in Sussex, England, by a small team of students, design conceived in 2013, built in 2014.

The gull wing sports car features a steel spaceframe, originally running on two or four 48 volt Lynch DC motors (40kW [53hp]), but designed to be upgraded to 200kW (268hp) all wheel drive, for a blistering 200mph performance, in a very stylish compact city sports car. Wow!

The running gear is from the Austin Metro range, disc/drum brakes combination, rubber cone suspension all round, wishbones at front, with trailing arms at the rear.

The only way to turbo-charge change, is with clean statute. Well done to the EU February 2023. Manufacturers will now have to build zero carbon cars. Let us hope they do not wait until the last minute. Energy companies will need to follow suite with infrastructure, or lose their grip on transport fuels. Great news for those considering entering the JVH2. At the moment it is the lack of alternative fuels at filling stations, that is the log jam.

The cartridge exchange system allows the operator to switch between compressed gas, liquid hydrogen, ammonia, or methanol, by way of future proofing the fuel cell powered electric vehicle. Since, at time of construction, and time of writing (March 2023) there was no infrastructure to support either of the technologies. There is though a move by the UK government to abolish sales of diesel and petrol powered vehicle by 2035. Meaning, the energy supply companies will have to get a move on.

This car was way ahead of it's time. Today, most FC EVs use compressed H2, at 350 or 700psi, in special high-pressure cylinders that are bolted into the vehicle. Using ammonia or methanol via a reformer is potentially much safer, though Toyota and Honda use cylinders, and there are also liquid hydrogen systems. All of which may be accommodated in a Smart Networked infrastructure.

Unfortunately for the student team that built this gull wing special, there was no such thing as the: "World Hydrogen Trophy," in 2014. The car ran nicely during development trials. The loading and unloading of cartridges was timed at 80 seconds and 100 seconds. But the carbon fibre bodywork was never completed, due to the extra expense - and disbanding of the team, who all have day jobs now. Maybe one day.

The cartridge system is compatible with the SmartNet® concept, energy load-levelling service stations, proposed as a solution to the waste of wind energy in the UK. This was suggested to UK officials and electricity distributors in 2021, but not acted on. It has even been suggested that the patent system might be amended to allow green patents to be filed, free of filing fees - to level the playing field for young innovators - when competing with giant automotive concerns. But this suggestion was also given the official cold shoulder by the minister responsible.

|

||||||||||

|

HISTORIC WORLD 1ST - INBUILT HYDROGEN CARTRIDGE EXCHANGE SYSTEM - SWAPS IN 2 MINS, TO AMMONIA OR METHANOL FUELS MEANING ANY VEHICLE SO EQUIPPED MAY USE ANY H2 COMPOUND - OR EVEN LITHIUM BATTERIES - FUTURE PROOFING TECHNOLOGY

ONE

MINUTE - Amoco pumps at one of the 'Minute' service stations

networked across the USA. For the first 25 years of motoring, petrol pumps did not exist. Instead, people were required to buy fuel in two-gallon cans from their nearest

chemist, hardware shop or hotel. The world’s first filling station was a

drugstore, still standing at Stadt-Apotheke – or Town Pharmacy – in Wiesloch, south of Heidelberg,

Germany. This was where Bertha Benz first refuelled her husband’s Motorwagen. Her

husband being Karl Benz. His 1886 patent for a horseless carriage is the first for an automobile designed to produce its own power. It was a tricycle with a motor, and used spoked-wire wheels, differential gears, and chains widely used on the bicycles of the day. Benz was a bicyclist.

|

||||||||||

|

Please use our A-Z INDEX to navigate this site or return HOME

This website is Copyright © 2023 Cleaner Ocean Foundation Ltd, equal opportunities companies. This website is carbon friendly, using less energy to load on average per page via simplicity & picture optimization. The same may not apply to third party links.

|